GREENHOUSE CULTIVATION

1. Designs and classification of greenhouse

Greenhouses are frames of inflated structure covered with a transparent material in which crops are grown under controlled environment conditions. Greenhouse cultivation as well as other modes of controlled environment cultivation have been evolved to create favorable micro-climates, which favours the crop production could be possible all through the year or part of the year as required. Greenhouses and other technologies for controlled environment plant production are associated with the off-season production of ornamentals and foods of high value in cold climate areas where outdoor production is not possible. The primary environmental parameter traditionally controlled is temperature, usually providing heat to overcome extreme cold conditions. However, environmental control can also include cooling to mitigate excessive temperatures, light control either shading or adding supplemental light, carbon dioxide levels, relative humidity, water, plant nutrients and pest control.

Classification of greenhouse based on suitability and cost

a) Low cost or low tech greenhouse

Low cost greenhouse is a simple structure constructed with locally available materials such as bamboo, timber etc. The ultra violet (UV) film is used as cladding materials. Unlike conventional or hi-tech greenhouses, no specific control device for regulating environmental parameters inside the greenhouse are provided. Simple techniques are, however, adopted for increasing or decreasing the temperature and humidity. Even light intensity can be reduced by incorporating shading materials like nets. The temperature can be reduced during summer by opening the side walls. Such structure is used as rain shelter for crop cultivation. Otherwise, inside temperature is increased when all sidewalls are covered with plastic film. This type of greenhouse is mainly suitable for cold climatic zone.

b) Medium-tech greenhouse

Greenhouse users prefers to have manually or semiautomatic control arrangement owing to minimum investment. This type of greenhouse is constructed using galvanized iron (G.I) pipes. The canopy cover is attached with structure with the help of screws. Whole structure is firmly fixed with the ground to withstand the disturbance against wind. Exhaust fans with thermostat are provided to control the temperature. Evaporative cooling pads and misting arrangements are also made to maintain a favourable humidity inside the greenhouse. As these system are semi-automatic, hence, require a lot of attention and care, and it is very difficult and cumbersome to maintain uniform environment throughout the cropping period. These greenhouses are suitable for dry and composite climatic zones.

c) Hi-tech greenhouse

To overcome some of the difficulties in medium-tech greenhouse, a hi-tech greenhouse where the entire device, controlling the environment parameters, are supported to function automatically.

Cost involved

1. Less expensive greenhouse without fan and pad Rs.300 to 500/m2

2. Medium cost greenhouse with pad and fan system Rs.800 to Rs.1100/m2

without automation

3. Expensive greenhouses with fully automatic Rs.2000 to Rs.3500/m2

control system

Other classifications

The greenhouse can also be classified based on type of structures, type of glazing, number of spans, environmental control etc. The various types are as follows.

Classification as per type of structure

a. Quonset type

b. Curved roof type

c. Gable roof type

Classification as per glazing

a. Glass glazing

b. Fiberglass reinforced plastic glazing

i. Plain sheet

ii. Corrugated sheet

c. Plastic film

i. Ultra violet stabilized low density poly ethylene

ii. Silpaulin

Classification based on number of spans

a. Free standing or single span

b. Multispan or ridge and furrow or gutter connected

Classification based on environmental control

a. Naturally ventilated

b. Passive ventilation

Poly house

The crops grown in open field are exposed to vivid environmental conditions, attack of insects and pests, whereas the polyhouse provides a more stable environment. Polyhouse can be divided in to two types

a) Naturally ventilated polyhouse

These polyhouse do not have any environmental control system except for the provision of adequate ventilation and fogger system to prevent basically the damage from weather aberrations and other natural agents..

b) Environmental controlled polyhouse

This type of polyhouse helps to extend the growing season or permits off-season production by way of controlling light, temperature, humidity, carbon-dioxide level and nature of root medium.

Carnation under high-tech greenhouse

Shade house

Shadehouses are used for the production of plants in warm climates or during summer months. Nurserymen use these structures for the growth of hydrangeas and azaleas during the summer months. Apart from nursery, flowers and foliages which require shade can also be grown in shadehouses. E.g. Orchids, These shade structures make excellent holding areas for field-grown stock while it is being prepared for shipping to retail outlets. Shadehouses are most often constructed as a pole-supported structure and covered with either lath (lathhouses) or polypropylene shade fabric. Polypropylene shadenets with various percentages of ventilations are used. Black, green, and white coloured nets are used, while black colours are the most preferred as it retains heat outside.

Top

2. Orientation of greenhouse / polyhouse

The design of greenhouse should be based upon sound scientific principles which facilitates controlled environment for the plant growth. Controlled environment plant production systems are used widely throughout the world to produce plant materials and products at a time or place, or of a quality that can not be obtained outdoors. Controlled environment agriculture requires far more capital investment per unit area than field agriculture and thus must essentially be correspondingly more intensive to justify investment costs. The greenhouse is a structure covered with a transparent material for admitting natural light for plant growth. The main components of greenhouse like structure, covering/glazing and temperature control systems need proper design for healthy growth of plants.

Under Indian conditions, Quonset type, multispan greenhouse is most suitable, because of its low cost and ease of fabrication. Ultra violet resistant low density polyethylene (UVLDPE) single film cladding of 200 micron thickness is sufficient for Naturally Ventilated ( NV) greenhouse and fan and pad (FP) greenhouses. This should be fully tightened by stretching on the structure to avoid fluter and tearing. It should not be nailed or screwed to the structure as it gives the chance for tearing. The T-Lock of LLock should be used for fastening the sheet at structure, as this does not tear the sheet and sheet replacement is easy.

Design

The structure has to carry the following loads and is to be designed accordingly.

a) Dead load: weight of all permanent construction, cladding, heating and cooling equipment, water pipes and all fixed service equipments to the frame.

b) Live load: weights superimposed by use (include hanging baskets, shelves and persons working on roof). The greenhouse has to be designed for a maximum of 15 kg per square meter live load. Each member of roof should be capable of supporting 45 kg of concentrated load when applied at its centre.

c) Wind load: The structure should be able to withstand winds of 110 kilometer per hour and at least 50 kg per square meter of wind pressure.

d) Snow load: These are to be taken as per the average snowfall of the location

The greenhouse should be able to take dead load plus live load or dead load plus wind load plus half the live load.

The greenhouses are to be fabricated out of Galvanized Iron Pipes. The foundation can be 60cmx60cmx60cm or 30 cm diameter and one meter depth in PCC of 1:4:8 ratio. The vertical poles should also be covered to the height of 60 cm by PCC with a thickness of 5cm. This avoids the rusting of the poles.

Orientation

Orientation of the greenhouse is a compromise for wind direction, latitude of location and type of temperature control. Single greenhouses with latitude above 40°N should have ridge running east to west to allow low angle light to enter from side rather than ends. Below 40°N the ridge of single greenhouses should be oriented from north to south, since the angle of sun is much higher. This orientation permits the movement of shadow of the gutter across the green house. The location and orientation of the greenhouse should avoid falling of shadow on the adjacent greenhouses. To avoid the shading effect from one green house to another greenhouse these should be oriented East to West. However, the wind direction and latitude are also to be considered.

Wind effects

If the greenhouse is naturally ventilated, the advantage of natural wind direction has to be taken to the maximum possible. The maximum dimension (length) of greenhouse should be perpendicular to the wind direction especially in summer. For fan and pad greenhouse the natural wind direction should be same as the air blown by fan.

Size of the greenhouse

The dimension of NAV GH should not be more than 50m x 50m. Bigger the

greenhouse, more will be the temperature build up due to poor ventilation. The length of evaporatively cooled greenhouse should not be more than 60m.

Spacing between greenhouses

The spacing between naturally ventilated green house should be 10 to 15 m so that the exhaust from one greenhouse should not enter the adjacent greenhouse.

Height of greenhouse

The maximum height can be up to 5m for 50m x 50m green house and this can be reduced as per the reduced size of the green house. Higher is the greenhouse more is the wind load for structure and glazing. The side ventilation can be of 2 m width and roof ventilation is 1m in width.

Structural design

The greenhouses are to be designed for necessary safety, serviceability, general structural integrity and suitability. The structure should be able to take all the necessary dead, live, wind and snow loads. The foundation, columns and trusses are to be designed accordingly. The greenhouse structures are to be designed to take up the loads as per design loads prescribed by the National Greenhouse Manufactures Association (NGMA of USA) standards –1994.

Top

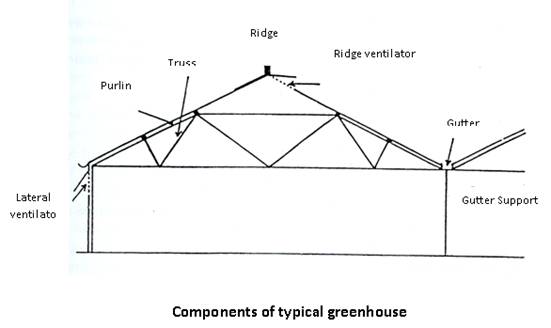

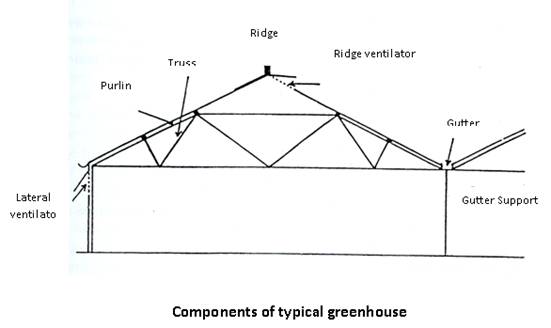

3. Components of greenhouse

Roof: transparent cover of a green house.

Gable: transparent wall of a green house

Cladding material: transparent material mounted on the walls and roof of a green house.

Rigid cladding material: cladding material with such a degree of rigidity that any deformation of the structure may result in damage to it. Ex. Glass

Flexible cladding material: cladding material with such a degree of flexibility that any deformation of the structure will not result in damage to it. Ex. Plastic film

Gutter: collects and drains rain water and snow which is place at an elevated level between two spans.

Column: vertical structure member carrying the green house structure

Purlin: a member who connects cladding supporting bars to the columns

Ridge: highest horizontal section in top of the roof

Girder: horizontal structure member, connecting columns on gutter height

Bracings: To support the structure against wind

Arches: Member supporting covering materials

Foundation pipe: Connection between the structure and ground

Span width: Center to center distance of the gutters in multispan houses

Green house length: dimension of the green house in the direction of gable

Green house width: dimension of the green house in the direction of the gutter |

Covering polyhouse with cladding material stage - I

Covering polyhouse with cladding material stage – II |

|

|

|

| Covering polyhouse with cladding material stage – III |

Covering polyhouse with cladding material stage – IV |

Covering polyhouse with cladding material stage – V |

|

|

| Covering polyhouse with cladding material stage – VI |

Greenhouse ready for takingup cultivation |

Cladding material

Polythene proves to be an economical cladding material. Now long lasting, unbreakable and light roofing panels-UV stabilized clear fiber glass and polycarbonate panels are available. Plastics are used in tropical and sub-tropical areas compared to glass/fiberglass owing to their economical feasibility. Plastics create enclosed ecosystems for plant growth. LDPE (low density polyethylene) / LLDPE (linear low density polyethylene) will last for 3-4 years compared to polythene without UV stabilizers.

Comparison of different kinds of covering materials

Sl.

No.

|

Type |

Durability |

Transmission |

Maintenance |

Light |

Heat |

1. |

Poly ethylene |

One year |

90% |

70% |

Very high |

2. |

Poly ethylene UV resistant |

Two years |

90% |

70% |

High |

3. |

Fiber Glass |

Seven years |

90% |

5% |

Low |

4. |

Tedlar coated Fiber Glass |

Fifteen years |

90% |

5% |

Low |

5. |

Double strength Glass |

Fifty years |

90% |

5% |

Low |

6. |

Poly carbonate |

Fifty years |

90% |

5% |

Very low |

Top

4. Plant growing structures / containers in greenhouse production

The duration of crop in greenhouse is the key to make the greenhouse technology profitable or the duration of production in greenhouses should be short. In this context, use of containers in greenhouse production assumes greater significance. The containers are used for the following activities in greenhouse production.

• Raising of seedlings in the nursery

• Growing plants in greenhouses for hybrid seed production of flowers

• Growing plants for cutflower production.

• Growing potted ornamental plants.

Advantages of containers in greenhouse production

• Increase in production capacity by reducing crop time.

• High quality of the greenhouse product

• Uniformity in plant growth with good vigour.

• Provide quick take off with little or no transplanting shock.

• Easy maintenance of sanitation in greenhouse

• Easy to handle, grade and shift or for transportation.

• Better water drainage and aeration in pot media.

• Easy to monitor chemical characteristics and plant nutrition with advanced

irrigation systems like drips.

Advantages and disadvantages of plant growing containers

Containers |

Advantages |

Disadvantages |

Clay pot |

Low cost

Easy water management |

Slow to work with pots and dry out fast

They are heavy to handle |

Fiber block |

Easy to handle |

Slow root penetration

Short life |

Fiber tray |

Minimum use of space |

Hard to handle when wet |

Single peat

Pallet |

No media preparation

Low storage requirement |

Requires individual handling Limited sizes can be handled |

Prespaced

Peat pallet |

No media preparation

Limited to small sizes |

Single peat |

Good root penetration |

Difficult to separate |

Pot |

Easy to handle in field Available (square / round) in large sizes |

Strip peat pot |

Good root penetration |

Slow to separate |

Protrays |

Easy to handle Reusable |

May be limited in sizes |

Plastic pack |

Easy to handle |

Roots may grow out of container |

Plastic pot |

Reusable

Good root penetration |

Requires handling as single plant |

Polyurethane foam |

Easy to handle Requires less medium Reusable |

Requires regular fertilization |

Soil band |

Good root penetration |

Requires extensive labour |

Soil block |

Excellent root penetration |

Expensive machinery |

Perforated |

Easy to handle |

Requires regular fertigation |

Plastic tray |

Requires less medium Available in many sizes reusable |

Roots may grow out of the container |

Perforated |

Less expensive |

Less durable |

Polyethylene |

Reusable bags |

Requires less storage space |

Selection of suitable containers depends upon the crop to be produced in greenhouse, plant characteristics like crop stage, duration, vigour, growth habit, root system, etc. Generally long duration, deep rooted and vigorous crop plants require bigger containers compared to short duration, shallow and less vigorous ones. The containers provide optimum condition for germination of seed and growth and development of transplants.

Top

5. Environmental factors influencing greenhouse cultivation

Plants need an optimum temperature for maximum yield and quality. The greenhouses in plain and coastal region of India needs cooling. The greenhouses in mild climates and coastal region can be naturally ventilated. The greenhouses for hot summer climates of northern plains have to evaporatively cooled or with fan and pad (FP). The greenhouses for northern plains may require both cooling and heating depending on the crop.

Natural ventilation

The greenhouse has to be thoroughly ventilated for control of temperature. It should be noticed that the temperature built up in the greenhouse is not exceeding 2°C throughout the year. Further during hot months the temperature in the greenhouse was same as the ambient temperature.

Unconventional method of heating and cooling

a) Hot and cold water can be sprinkled on the greenhouse covered externally with

the shadenet

b) Use of earth tunnel for cooling in summer and heating in winter

c) Construction of greenhouse in a trench for heating in winter cooling in summer

d) Circulating the borewell water in pipes laid on the floor of the greenhouse

Heating of greenhouse

The heating of greenhouses in cold climates like winter in North India or

Himalayan Region at high altitudes is advisable for getting better produce. Double

covering of glazing with an air cushion of 2 cm to 10 cm reduces the heating load

considerably.

Heating systems

These can be of the following types

a. Boiler

1. With hot water tube

2. With steam pipes

b. Unit heaters

c. Infrared heaters

d. Solar heaters

Boiler

This system is used for very big greenhouses and is a centralized system of heating. The boiler of necessary capacity is provided in the greenhouse. The fuel for boiler can be coal or fuel oil. The heating of the greenhouse is generally done through hot water at 85°C or steam at 102°C. Water or steam pipes are installed above the beds of crop and along the side wall. The steam system is cheaper than hot water system. To reduce the length of pipe to be used a number of hot water or steam pipe coils can be used and green house air circulated over them by blower for heating.

Unit heaters

These are localized system of heating and a number of unit heaters are to be provided in the greenhouse at a height of about 3 meter to distribute heat evenly in the greenhouse. In a unit heater the fuel is combusted in the chamber at bottom. Hot fumes rise inside the heat exchanger tubes, giving heat to the walls of the tubes. Smoke exists at the top. A fan forces cool air of the greenhouse over the outside of heat exchange tubes, where it picks up heat.

Infra-red heaters

The fuel gas (LPG) is burnt and the fumes at a temperature of about 480°C are passed in 10 cm diameter pipes kept overhead at a height of 1.5m above plants. Reflectors are provided over the full length of pipe to radiate the infra red rays over the plants. The plants and soil only get heated without much heating of air. The infra red heating pipes can be provided at 6 to 10 meters interval all along the length of greenhouse. The temperature of fume gases at exist is about 65°C and exhaust fan is provided for maintaining the flow of fumes.

Solar heating

Flat plate solar heaters are used to heat the water during day time. The hot water is stored in the insulated tanks. The hot water is circulated in pipes provided along the length of the greenhouse during night. Supplementary or emergency heating systems are provided for heating the greenhouse during cloudy or rainy days.

Environmental control

Temperature control

The thermostat can be coupled to water circulating pump or exhaust fan for controlling the temperature inside the greenhouse. However, the lowest achievable temperature in fan and pad greenhouse is not below the wet bulb temperature in any case.

Relative humidity control

The humidistat coupled to water circulating pump or exhaust fan to control the relative humidity inside the fan and pad greenhouse. The maximum achievable relative humidity is 90% only in fan regulated (FR) greenhouse. The RH in Non ventilated (NV) GH can be increased by providing foggers.

Light intensity control

In certain areas where natural illumination is absent or very low, illumination for plants may be provided by artificial sources. Incandescent bulbs generate excessive heat and are unsatisfactory in most instances. Fluorescent tubes are useful as the sole source of light for African violets, gloxinias and many foliage plants which grow satisfactorily at low light intensities. Excessive light intensity destroys chlorophyll even though the synthesis of this green pigment in many plants is dependent upon light. Chrysanthemum is a classic example for a short-day plant., however, flower buds will not form unless the night temperature is high enough. Chrysanthemum is flowered on a year-round basis as a cut flower or potted plant simply by controlling the length of day and temperature.

Quality of light

Quality of light refers to its wave-length composition. Light in the orange-red portion of the visible spectrum from either sunlight or artificial illumination is most effective in causing the long-day response in plants. Far-red radiation appears to have the opposite effect. It is probable that the wave lengths activate some hormonal mechanism within the plant which brings about the specific effect of light on growth or flowering.

Fan and pad

Selection of fan

The fans should deliver the required air at 15mm static pressure. The maximum center to center spacing between the tow fans should be of 7.5m. The height of the fans is to be determined based on the plant height which is proposed to be grown in the greenhouse. The fan blades and frame are to be made of non-corrosive materials like aluminium/stainless steel.

Design

The cross fluted cellulose pad is preferred. These are available mostly in 100mm thickness. One meter of pad height is given for every 20m of pad to fan distance. How ever, the fan to pad distance should not exceed 60m. The air flow rate should be of 75 cubic meter/minute/sq.m of pad. The water flow rate should be of 9 litres per minute/linear meter pad. The uniform distribution of water on pad is to be maintained.

Maintenance of pad

The algae will grow and salts will deposit on pads if these are not maintained properly. Good control of algae can be obtained without using chemicals by the following methods.

1. By shading the pads and sumps

2. By drying the pads daily

3. By avoiding nutrient contamination

4. By draining and disinfecting the sump regularly

5. By replenishing 20% of circulating water each time to avoid scaling of minerals.

Maintenance of fan

1. The lubrication of bearings should be done regularly

2. The v belt should be tightened as per requirement

3. The levers should be properly lubricated.

Top

6. Media preparation and fumigation

Soil mixes used for greenhouse production of potted plants and cut flowers are highly modified mixtures of soil, organic and inorganic materials. When top soil is included as a portion of the mixture, it is generally combined with other materials to improve the water holding capacity and aeration of the potting soil. Many greenhouses do not use topsoil as an additive to the soil mixes, but rather use a combination of these organic and inorganic components as an artificial soil mix. When managed properly as to watering and fertilization practices, these artificial mixes grow crops that are equal to those grown in top soil.

Media preparation for greenhouse production

The media used in greenhouse generally have physical and chemical properties which are distinct from field soils.

-

A desirable medium should be a good balance between physical properties like water holding capacity and porosity.

-

The medium should be well drained.

-

Medium which is too compact creates problems of drainage and aeration which will lead to poor root growth and may harbour disease causing organisms.

-

Highly porous medium will have low water and nutrient holding capacity, affects the plant growth and development.

-

The media reaction (pH of 5.0 to 7.0 and the soluble salt (EC) level of 0.4 to 1.4 dS/m is optimum for most of the greenhouse crops).

-

A low media pH (<5.0) leads to toxicity of micronutrients such as iron, zinc, manganese and copper and deficiency of major and secondary nutrients while a high pH (>7.5) causes deficiency of micronutrients including boron.

-

A low pH of the growth media can be raised to a desired level by using amendments like lime (calcium carbonate) and dolomite (Ca-Mg carbonate) and basic, fertilizers like calcium nitrate, calcium cyanamide, sodium nitrate and potassium nitrate.

-

A high pH of the media can be reduced by amendments like sulphur, gypsum and Epsom salts, acidic fertilizers like urea, ammonium sulphate, ammonium nitrate, mono ammonium phosphate and aqua ammonia and acids like phosphoric and sulphuric acids.

-

It is essential to maintain a temperature of the plug mix between 70 to 75ºF. Irrigation through mist is a must in plug growing. Misting for 12 seconds every 12 minutes on cloudy days and 12 seconds every 6 minutes on sunny days is desirable.

-

The pH of water and mix should be monitored regularly.

Gravel culture

Gravel culture is a general term which applies to the growing of plants with out soil in an inert medium into which nutrient solutions are usually pumped automatically at regular intervals. Haydite (shale and clay fused at high temperatures), soft- or hard-coal cinders, limestone chips, calcareous gravel, silica gravel, crushed granite and other inert and slowly decomposing materials are included in the term “gravel”. The more important greenhouse flowering crops include roses, carnations, chrysanthemums, gardenias, snapdragons, lilies, asters, pansies, annual chrysanthemums, dahlias, bachelor buttons and others.

Desirable nutrient level in greenhouse growth media

S. No. |

Category |

Concentration (mg/l) |

NO3 |

N |

P |

K |

1. |

Transplants |

75 |

125 |

10-15 |

250-300 |

2. |

Young pot & foliage plants |

50 |

90 |

6-10 |

150-200 |

3. |

Plants in beds |

125 |

225 |

10-15 |

200-300 |

Media ingredients and Mix

Commercially available materials like peat, sphagnum moss, vermiculite, perlite and locally available materials like sand, red soil, common manure/ compost and rice husk can be used in different proportions to grow greenhouse crops. These ingredients should be of high quality to prepare a good mix. They should be free from undesirable toxic elements like nickel, chromium, cadmium, lead etc.

Pasteurization of greenhouse plant growing media

Greenhouse growing medium may contain harmful disease causing organisms, nematodes, insects and weed seeds, so it should be decontaminated by heat treatment or by treating with volatile chemicals like methyl bromide, chloropicrin etc.

Agent |

Method |

Recommendation |

Heat |

Steam |

30 min at 180° F |

Methyl bromide |

10 ml/cu. ft. of medium |

Cover with gas proof cover for 24-48 hr. Aerate for 24-28 hr before use. |

Chloropicrin |

(Tear gas) 3-5 ml/cu. ft. of medium |

Cover for 1-3 days with gas proof cover after sprinkling with water. Aerate for 14 days or until no odour is detected before using. |

Basamid |

8.0 g/cu.ft. of medium |

Cover for 7 days with gas proof cover and aerate for atleast a week before use. |

Formalin |

20 ml/l of water (37%) |

Apply 2 l/cu.ft. cover for 14 to 36 hr and aerate for at least 14 days. |

Disinfection of the growing media can also be achieved by fungicides or bactericides

Fungicides and their effect on a few fungi

Chemical |

Rate of application |

Effect against |

Captan |

2 g/l of water |

Pythium, Fusarium, Rhizoctonia and Phytophthora. Some extent to root and stem rot, white mold,black rot, crown rot and damping off. |

Metalaxyl + Mancozeb (Ridomil MZ 72 WP) |

1 g/l of water |

Pythium, Phytophthora, Fusarium and other soil borne pathogens |

Temperature necessary to kill soil pests

- 115°F for water molds (Pythium and Phytophthora)

- 120°F for nematodes

- 135°F for worms, slugs and centipedes

- 140°F for most plant pathogenic bacteria

- 160°F for soil insects

- 180°F for most of weed seeds

- 200°F for few resistant weed seeds and plant viruses

Fumigation in greenhouse

Physical propagation facilities such as the propagation room, containers, flats, knives, working surface, benches etc. can be disinfected using one part of formalin in fifty parts of water or one part sodium hypochlorite in nine parts of water. An insecticide such as dichlorvos sprayed regularly will take care of the insects present if any. Care should be taken to disinfect the seed or the planting materials before they are moved into the greenhouse with a recommended seed treatment chemical for seeds and a fungicide –insecticide combination for cuttings and plugs respectively. Disinfectant solution such as trisodium phosphate or potassium permanganate placed at the entry of the greenhouse would help to get rid off the pathogens from the personnel entering the greenhouses.

Top

7. Drip irrigation and fertigation systems in greenhouse cultivation

The plant is required to take up very large amounts of water and nutrients, with a relatively small root system, and manufacture photosynthates for a large amount of flower per unit area with a foliar system relatively small in relation to required production.

Watering system

Micro irrigation system is the best for watering plants in a greenhouse. Micro sprinklers or drip irrigation equipments can be used. Basically the watering system should ensure that water does not fall on the leaves or flowers as it leads to disease and scorching problems. In micro sprinkler system, water under high pressure is forced through nozzles arranged on a supporting stand at about 1 feet height. This facilitates watering at the base level of the plants.

Equipments required for drip irrigation system include

i) A pump unit to generate 2.8kg/cm2 pressure

ii) Water filtration system – sand/silica/screen filters

iii) PVC tubing with dripper or emitters

Drippers of different types are available

i) Labyrinth drippers

ii) Turbo drippers

iii) Pressure compensating drippers – contain silicon membrane which assures uniform flow rate for years

iv) Button drippers- easy and simple to clean. These are good for pots, orchards and are available with side outlet/top outlet or micro tube out let

v) Pot drippers – cones with long tube

Water out put in drippers

a. 16mm dripper at 2.8kg/cm2 pressure gives 2.65 litres/hour ( LPH).

b. 15mm dripper at 1 kg/cm2 pressure gives 1 to 4 litres per hour

Filters: Depending upon the type of water, different kinds of filters can be used.

Gravel filter: Used for filtration of water obtained for open canals and reservoirs that are contaminated by organic impurities, algae etc. The filtering is done by beds of basalt or quartz.

Hydrocyclone: Used to filter well or river water that carries sand particles.

Disc flitersL: Used to remove fine particles suspended in water

Screen filters: Stainless steel screen of 120 mesh ( 0.13mm) size. This is used for second stage filtration of irrigation water.

Fertigation system

In fertigation system an automatic mixing and dispensing unit is installed which consists of three systems pump and a supplying device. The fertilizers are dissolved separately in tanks and are mixed in a given ratio and supplied to the plants through drippers.

Fertilizers

Fertilizer dosage has to be dependent on growing media. Soilless mixes have lower nutrient holding capacity and therefore require more frequent fertilizer application. Essential elements are at their maximum availability in the pH range of 5.5 to 6.5. In general Micro elements are more readily available at lower pH ranges, while macro elements are more readily available at pH 6 and higher.

Forms of inorganic fertilizers

Dry fertilizers, slow release fertilizer and liquid fertilizer are commonly used in green houses.

Slow release fertilizer

They release the nutrient into the medium over a period of several months. These fertilizer granules are coated with porous plastic. When the granules become moistened the fertilizer inside is released slowly into the root medium. An important thing to be kept in mind regarding these fertilizers is that, they should never be added to the soil media before steaming or heating of media. Heating melts the plastic coating and releases all the fertilizer into the root medium at once. The high acidity would burn the root zone.

Liquid fertilizer

These are 100 per cent water soluble. These comes in powdered form. This can be either single nutrient or complete fertilizer. They have to be dissolved in warm water.

Fertilizer Application Methods

1. Constant feed

Low concentration at every irrigation are much better. This provides continuous supply of nutrient to plant growth and results in steady growth of the plant. Fertilization with each watering is referred as fertigation.

2. Intermittent application

Liquid fertilizer is applied in regular intervals of weekly, biweekly or even

monthly. The problem with this is wide variability in the availability of fertilizer in the root zone. At the time of application, high concentration of fertilizer will be available in the root zone and the plant immediately starts absorbing it. By the time next application is made there will be low or non existent. This fluctuation results in uneven plant growth rates, even stress and poor quality crop.

Fertilizer injectors

This device inject small amount of concentrated liquid fertilizer directly into the water lines so that green house crops are fertilized with every watering.

Multiple injectors

Multiple injectors are necessary when incompatible fertilizers are to be used for fertigation. Incompatible fertilizers when mixed together as concentrates form solid precipitates. This would change nutrient content of the stock solution and also would clog the siphon tube and injector. Multiple injectors would avoid this problem. These injectors can be of computer controlled H.E. ANDERSON is one of the popular multiple injector.

Fertilizer Injectors

Fertilizer injectors are of two basic types: Those that inject concentrated fertilizer into water lines on the basis of the venturi principle and those that inject using positive displacement

A. Venturi Principle Injectors

1.Basically these injectors work by means of a pressure difference between the irrigation line and the fertilizer stock tank.

a) The most common example of this is the HOZON proportioner.

b) Low pressure, or a suction, is created at the faucet connection of the Hozon at the suction tube opening. This draws up the fertilizer from the stock tank and is blended in to the irrigation water flowing through the Hozon faucet connection.

c) The average ratio of Hozon proportioners is 1:16. However, Hozon proportioners are not very precise as the ratio can vary widely depending on the water pressure.

d) These injectors are inexpensive and are suitable for small areas. Large amounts of fertilizer application would require huge stock tanks due to its narrow ratio.

B. Positive displacement injectors.

1. These injectors are more expensive than Hozon types, but are very accurate in proportioning fertilizer into irrigation lines regardless of water pressure.

2. These injectors also have a much broader ratio with 1:100 and 1:200 ratio being the most common. Thus, stock tanks for large applications areas are of manageable size and these injectors have much larger flow rates.

3. Injection by these proportioners is controlled either by a water pump or an electrical pump.

4. Anderson injectors are very popular in the greenhouse industry with single and multiple head models.

a.Ratios vary from 1:100 to 1:1000 by means of a dial on the pump head for feeding flexibility.

b.Multihead installations permit feeding several fertilizers simultaneously without mixing. This is especially significant for fertilizers that are incompatible (forming precipitates, etc.) when mixed together in concentrated form.

5. Dosatron feature variable ratios (1:50 to 1:500) and a plain water bypass.

6. Plus injectors also feature variable ratios (1:50 to 1:1000) and operates on water pressure as low as 7 GPM.

7. Gewa injectors actually inject fertilizer into the irrigation lines by pressure.

a. The fertilizer is contained in a rubber bag inside the metal tank.

Water pressure forces the fertilizer out of the bag into the water supply.

b. Care must be taken when filling the bags as they can tear.

c. Ratios are variable from 1:15 to 1:300.

8. If your injector is installed directly in a water line, be sure to install a bypass

around the injector so irrigations of plain water can be accomplished.

General problems of fertigation

Nitrogen tends to accumulate at the peripherous of wetted soil volume. Hence, only roots at the periphery of the wetted zone alone will have enough access to Nitrogen. Nitrogen is lost by leaching and denitrification. Since downward movement results in permanent loss of NO3 –N, increased discharge rate results in lateral movement of N and reduces loss by leaching.

Phosphorous

It accumulates near emitter and P fixing capacity decides its efficiency. Low pH near the emitter results in high fixation.

Potassium

It moves both laterally and downward and does not accumulate near emitter. Its distribution is more uniform than N&P.

Micronutrients

Excepting boron, all micronutrients accumulates near the emitter if supplied by fertigation. Boron is lost by leaching in a sandy soil low in organic matter. But chelated micronutrients of Fe, Zn can move away from the emitter but not far away from the rooting zone.

Top

8. Cost estimation for green house construction

A model project proposal for floriculture industry

A. Title of the project:

Title should be brief and apt. It should be indicate clearly the main business activity. Eg. Production of Rose cut flowers for domestic and export market.

B. Introduction:

Give a line of introduction of the proposed business. Justification for starting the business, scope and competition should be clearly stated.

C. Production technology:

Give detailed account of the entire production process along with the scientific basis for each step.

D. Project components: For cut flower production

1. Land

2. Greenhouse

3. Planting material

4. Irrigation

5. Fertilization system

6. Grading and packing room

7. Refrigerated van

8. Office equipment

9. Import of technology

10. Labour charge

11. Technical manpower

12. Pesticides, Fertilizers, preservatives

Give the costing for each of the major components and classify them into

A. Fixed cost –Permanent items

B. Recurring cost –planting, cultivation, maintenance, storage, packing and transportation costs.

E. Project yield

Estimate the total production expected in different years and the realization expected through sales.

F. Margin money

25% of the total cost that has to be invested by the entrepreneur.

G. Repayment

Principal and interest are to be repayable in seven years with a moratorium for the first year on interest and for 2 years on principal.

Budget requirement

For a one hectare greenhouse to produce Rose cut flowers.

A. Fixed cost

S. No. |

Item |

Amount in lakhs |

| 1. |

Land and development |

4.0 |

| 2. |

Green house |

13.0 |

| 3. |

Cold storage |

10.0 |

| 4. |

Grading and packing room |

5.0 |

| 5. |

Office area |

2.5 |

| 6. |

Refrigerated van |

1.0 |

| 7. |

Generator set |

2.0 |

| 8. |

Fax, telephone, Computer |

1.0 |

| 9. |

Furniture |

0.5 |

| 10. |

Power supply installations |

1.5 |

| 11. |

Water supply system, drip irrigation and misting liners |

6.0 |

| 12. |

Planting material and planting |

30.0 |

| Total fixed cost |

76.5 lakhs |

B. Recurring costs

S. No. |

Item |

Amount in lakhs |

| 1. |

Electricity charges / year |

6.0 |

| 2. |

Manures and fertilizers |

1.0 |

| 3. |

Plant protection |

1.0 |

| 4. |

Preservatives |

3.0 |

| 5. |

Packing material |

2.0 |

| 6. |

Air freight |

125.0 |

| 7. |

Labour charges |

3.0 |

| 8. |

Commission / duty/ insurance |

15.0 |

| 9. |

Salaries |

5.0 |

| 10. |

Overhead costs |

0.5 |

| 11. |

Maintenance cost |

1.0 |

| 12. |

Miscellaneous |

3.7 |

| Total recurring cost |

166.2 |

Total investment for the project = Fixed cost + Recurring cost = 76.5 + 166.2 in first year= 242.7.

Project yield

No. of rose plants per hectare of greenhouse = 60,000

No. of flowers expected per plant = 100 to 150

No. of exportable quality flowers /plant = 60 to 100

Price per flower in international market = Rs. 6 to 11

Total exportable flowers /ha @ 100 flowers /plant = 60 lakhs flowers

Gross income through exports @ 50 flowers/plant = 300 lakhs (minimum).

Top

9. Problem management in greenhouse cultivation

The troubles which arise in the culture of crops in the greenhouse may be divided into several groups a) failure to supply the essential factors for optimum growth such as light, moisture, carbon dioxide and heat in amounts necessary for each individual crop b) fertilizer deficiencies c) fertilizer excesses d) toxic gases e) attacks by insects, animals, and allied pests and f) susceptibility to fungus, bacteria and virus troubles.

Fertilizer deficiencies

Symptoms of deficiencies of various fertilizers have been studied over a period of years with plants in greenhouses.

Chlorosis

This is a term used to denote the loss of normal green colour from the foliage whether it is on the older, more mature leaves or the younger foliage. The entire leaf may be affected, or just areas between the veins, in which case the yellowing is most usually in irregular patches shading into the green colour. Sometimes only the margin of the leaf or leaflets may be yellow, while the centre of the foliage is almost a normal green.

Necrosis

This refers to the death of the area severely affected by chlorosis. Necrotic spots or areas can also be caused by spray or aerosol damage, sunscald and other such factors which may have no relation of fertilizer.

Nitrogen deficiency

Generally the entire plant becomes lighter green, but the effect will be most noticeable on the older foliage. Gradually the oldest leaves loose their green colour, and most plants become yellow. The flowers are smaller and may lack well-developed colour.

Phosphorus deficiency

A purplish coloration developing first on the underside of the petiole, or leaf stem, which spreads to the main veins of the leaf is characteristic of this deficiency.

Potassium deficiency

The margins of the leaves of the older foliage become yellow, and the chlorosis progresses toward the mid-portion of the foliage as this deficiency increases in severity. The older leaves may drop in extreme cases of deficiency. Certain fumigants may cause marginal burning or chlorosis, and sometimes droplets of spray or fumigant may result in spots or blotches of chlorotic or necrotic nature.

Calcium deficiency

In sand culture, a typical symptom is the development of short clubby roots followed in a matter of several weeks by their death. In many cases insufficient calcium is associated with a low pH of the soil.

Iron deficiency

This is a rather common trouble although an actual lack of iron may not be the primary cause. As iron deficiency becomes more intense, necrotic areas appear on scattered portions of the yellow coloured leaves and the affected foliage may drop. Iron can become deficient in soil, but often the symptoms of this deficiency are induced by other causes from injury to the roots by over-watering or over fertilization. Nematodes, or other soil pests interfering with root growth can also induce iron chlorosis symptoms.

Boron deficiency

The number of cases where this is a limiting factor are few, and most of them are with certain rose and carnation varieties. The new foliage is thick or leathery and quickly becomes chlorotic. The rose flowers are usually very malformed. The stem tip dies, giving rise to growth of shoots immediately below, which in turn die at the tip, and a ‘witches broom’ effect is observed. Because deficiency symptoms can sometimes be confused with the effects of some other environmental factor of cultural practice, a thorough review of fertilizer application, soil testing, soil type, watering practices, and other procedures is warranted before hasty conclusions are reached.

Fertilizer excesses

An unfortunate belief among many growers is that when a plant does not grow under apparently favorable conditions, the trouble can be overcome by applications of fertilizer. This practice has resulted in untold damage or loss of crops, as more often than not the original trouble could have been too much fertilizer in the soil. If additional fertilizer is applied when no more is needed, the results can be very injurious. Sometimes the difference between a high but safe nutrient level and an injurious nutrient level is not very great and the margin of safety may be extremely small. Therefore, it behaves the grower to test the soil in case of doubt to determine the advisability of fertilizer application.

Nitrogen excess

The plants exhibit heavy, rank growth, with large, dark green leaves that are often crisp and break easily. Additional nitrogen may inhibit root action, causing typical symptoms of iron chlorosis. If the root system is killed, the plants wilt excessively and never recover. This yellowing of the top foliage is very common in chrysanthemums and snapdragons. Over 75 ppm of nitrates is not safe.

Phosphorus excess

Over doses of phosphorus precipitate the iron from the soil solution and make it insoluble and unavailable, causing iron chlorosis to develop. Over 25 ppm may cause trouble.

Potassium excess

Up to a certain point, excessive potash apparently is not injurious. Greater amounts inhibit root action and may cause chlorosis, wilting, or immediate death of the plant. Over 60ppm is dangerous.

Calcium excess

Usually the pH of the soil will rise when there is excessive calcium. This causes iron chlorosis in many plants and has been called over liming injury. Over 300 ppm is high.

Iron excess

In the normal pH range of soil, there is little danger of excessive iron since phosphorus or calcium will precipitate it from the soil solution. At ph 5.0 or lower, iron becomes very soluble, and on hydrangeas brown dots appear on the leaves, indicating iron is being precipitated as water vapor is lost by transpiration.

Sulfate excess

A low pH may often be characteristic of soils high in sulfates. Sometimes high sulfates are encountered at pH 6.5. Over 600 ppm is toxic to most plants.

Boron excess

This trace elements is often found in soil to which unleached cinders have been added or where boric acid has been applied indiscriminately. Certain water supplies may have rather high amounts of boron. On roses, the serrations on the margin of the leaflets of the lower leaves turn black and the remaining leaves turn yellow and drop.

Aluminum excess

This is not troublesome except on hydrangeas that are being blued. Roots are burnt, and the plants wilt.

Soluble salts excess

Too much fertilizers in the soil injures or kills roots, and plant growth is severely reduced.

Remedial measures for excess fertilizer

When fertilizer levels rise to the point where they become toxic, immediate steps must be taken to remove the excessive materials. Excessive nitrogen leaching with heavy waterings and application of of straw mulch Excessive phosphorus can not be leached. Only by addition of lime or iron sulfate Excessive potassium leaching may wash some quantity, but in clay soils removal may be almost impossible. Excessive calcium Acidifying the soil excessive iron Raising the pH or by addition of phosphorus excessive sulfates Leaching and avoiding the use of sulfate forms of fertilizers excessive boron Water glass, or sodium silicate can be dissolved in water at the rate of 100 cubic centimeters per gallon and applied to the soil. Excessive aluminum raising the pH or by adding phosphorus excessive soluble salts leaching.

Injury by toxic gases

Natural gas

This gas usually contains 95 per cent methane and 4 to 5 per cent ethane and frequently causes injury to greenhouse plants. The common source of injury is from corroded or leaky gas pipes inside or outside the greenhouse. This injuries usually occur during winter when the ventilators kept closed. Very small concentrations of gas are sufficient to cause damage to plants, its detection is difficult by sense of smell. One part to 350 will cause a headache after 2 hours, whereas 1 part of natural gas in 10,000 to 100,000 of air will injure many plants. The best method of detection is through the use of tomato plants. In the presence of gas the leaves of tomato turn downward, because of epinastic response, which causes petioles of leaves to grow more rapidly on the upper side. Carnations exposed to low concentrations will develop long stigmas, but this may also occur in bright weather in unshaded greenhouses. In case of prolonged exposure of young buds even 1 part to 100,000 may kill the buds and flowers fail to develop. Rose foliage on the upper shoots exhibits epinasty, or a bending downward of the petiole. Severe leaf drop may follow and the flower colour often fades. Bulbous plants usually develop twisted foliage and the flowers do not open properly.

Ethylene gas

This gas apparently is a by-product of metabolic processes and is given off in very small quantities by plants or their parts. Dropping of flowers after pollination is thought to be associated with ethylene vapors. The carnation flowers close or may appear “sleepy”, that is, the ends of the petals curl inward due to ethylene gas.

Sulphur dioxide

In very low concentrations this gas is toxic to plants. Sulphur dioxide enters the leaf through open stomata and kills the cells nearby, thus showing patches of dead tissues scattered over the leaf and frequently affecting the margins. Middle-aged leaves are more susceptible than young leaves.

Damage from sulphur dioxide is commonly found in localities where coal is burnt in large quantities. Foggy days are particularly dangerous. The common practice of using sulphur on heating pipes in rose houses to control mildew is responsible for leaf drop on some varieties.

Mercury damage

Many plants are quickly damaged by vapors from metallic mercury. This damage is manifested in roses by peduncles of young buds turning yellow and later black. The color of flowers turns dark and leaves are scorched. Breaking of mercury thermometers or the use of bi chloride of mercury on beds as a disinfectant is the usual way in which mercury may be released. Control measures consist of removing all possible traces of mercury and covering the areas where mercury was spilled or applied with a 2-inch thickness of iron filings. Paint containing mercury as a fungicide should not be applied to rose houses.

2,4-D

The fumes of 2,4- dichlorophenoxy acetic acid and related compounds used as weed killers cause bending, curling, and other malformations of leaves, stems, flowers or bracts. Fumes or ‘drift’ from a spray applied along the side of a greenhouse may enter through the doors or side vents cause trouble. Therefore, it is well to prevent trouble by keeping such sources of potential damage out of the greenhouse, boiler room, potting shed, or any place where the fumes could conceivably enter a greenhouse.

Phenol compounds

Many materials containing phenol or its derivatives are toxic to plants. Tar, carbolic acid, pentachlorophenol and many others of similar nature should never be used under glass. Treatment of wooden bench members with wood preservatives containing phenol compounds results in severe damage to the plants.

Top

10. Special horticultural practices in greenhouse production

The aim of greenhouse cultivation is to obtain high yield and good quality flower with in a short period. Several methods for forcing flowers can be used successfully to obtain high yield and quality.

Rose

Deshooting

Sprouting of buds just below flower, from the point between shoot and leaf lead

to smaller bud size. So these shoots should be removed regularly.

Dead shoot removal

In the old plants the dead shoot or dried shoots on plants are observed which will

be the host for fungi. So regulary these have to be removed.

Soil loosening on beds

After 6 months or so, there is every chance that the soil become stony and it has

to be loosened for efficient irrigation.

Bending

Leaf is a source of food for every plant. There should be balance between

source (assimilation ) and sink (Dissimilation).

Mother shoot bending

After planting 2 to 3 eye buds will sprout on main branch, these sprouts will grow as branches and these branches in turn form buds. This is don’t to initiate bottom breaks or ground shoots which will form main framework of plant structure. The mother shoot is bend on 2nd leaf or nearer to the crown region. The first bottom break or ground shoot will start coming from the base. These ground shoots form the basic framework for production and thereon the ground shoots should be cut at 5th five pair of leaves and medium ground shoots should be cut at 2nd or 3rd five pair of leaves.

Defoliation

The removal of leaves is known as defoliation. It is done mainly to induce certain plant species to flower or to reduce transpiration loss during periods of stress. Defoliation may be done by removal of leaves manually or by withholding water. The shoots are defoliated after pruning.

Carnation

Support system (Netting)

Good support material is metal wire mesh width of 7.5 x 7.5 cm to 15 x 15 cm. The cheapest support material is net with nylon. Minimum at every 3 meters, the wires should be supported with poles. The poles at the beginning and the end of each bed should be strong enough and be in cast concrete. For an optimal support of the crop, an increasing width of meshes may be used. Eg. The bottom net of 7.5 x 7.5 cm, then 12.5 x 12.5 cm and the upper nets 15 x 15 cm.

Pinching

Pinching refers to breaking out the tip of shoot with few leaves and encouraging growth of side shoots. There are three types of pinching

a) single b) one and half and c) double pinches

Pinching is done at a stage when the plants are young and between of 7-15cm height. Since very tender shoots are usually pinched, no special tool is required. It is done by snapping the shoot tip manually. A sharp knife or blade may be used for pinching. When the plant attains 6 nodes, the first pinch is given. This is referred as ‘single pinch’. This would give rise to six lateral shoots. With a ‘ one and half pinch’, 2-3 of these lateral shoots are pinched again. For the ‘double pinch’ all the lateral shoots are pinched off. Other than carnation, pinching is also practiced in marigold, Gomphrena (single pinch), and spray types of chrysanthemum (double pinch).

Disbudding

Disbudding refers to removal of side shoots so that the central/terminal bud receives maximum food for the full development. In standard carnations, side buds should be removed where as in spray carnations, the terminal bud has to be removed.

Chrysanthemum

Pinching out the apical bud

As soon as the bud stems begin to elongate in other words as soon as the buds have just separated from one another, it is used to pinch out the central bud, this improves the spray shape. If pinching out is done too early, damage may be caused to the side buds, so it is carried out between 2nd and 3rd weeks before harvesting.

Top

11. Physiological disorders

Plant disorders may be either due to nutritional deficiencies or unsuitable growing storage conditions. In appropriate temperature atmospheric or erratic water or food supply, poor light, unsatisfactory atmospheric conditions may also cause deficiencies of the mineral salts that are essential for healthy plant growth.

Rose

Blind wood

The normal flowering shoot on a greenhouse rose possesses fully expanded sepals, petals, and reproductive parts. The failure to develop a flower on the apical end of the stem is a common occurrence-such shoots are termed blind. The sepals and petals are present, but the reproductive parts are absent or aborted. Blind wood is generally short and thin, but it may attain considerable length and thickness when it develops at the top of the plant. This may be caused by insufficient light, chemical residues, insect, pests, fungal diseases and other factors.

Bull heads or malformed flowers

The center petals of the bud remain only partly developed and the bud appears flat. They are common on very vigorous shoots, particularly bottom breaks, and it is possible that there is a lack of carbohydrates to develop the petals. The cause of bull heading is as yet unknown, how ever, thrips infestation will also cause malformed flowers.

Colour fading

Off- coloured flowers present a problem with some yellow varieties in that the petals may be green or a dirty white instead of a clear yellow. Raising the night temperature several degrees will reduce the number of off-coloured flowers. Occasionally the pink or red varieties develop bluish-coloured flowers. This is very often associated with use of organic phosphate and various other kinds of insecticides.

Limp necks

The area of the stem just below the flower “wilts” and will not support the head. Sometimes this is due to insufficient water absorption; cutting off the lower 1 to 2 inches of stem and placing the cut stem in water at 37°C will revive the flower.

Blackening of rose petals

This is caused by low temperature and high anthocyanin content. GA3 treatment causes accumulation of anthocyanin in petals of Baccara roses. This effect was more pronounced at low temperature (20°C at day and 4°C at night) than in higher temperature (30°C at day and 20°C at night).

Nutritional disorders

Iron deficiencies can cause pale foliage. Adjusting the pH of the soil may solve this problem

Carnation

Splitting of calyx

The calyx may split down either half or completely. The petals are deprived of their support, which results into bending down of petals. Thus, the regularity of shape and structure of the flower destroyed. Splitting is associated with weather, particularly where light and temperature fluctuate. Some reduction in splitting can be obtained by keeping the night temperature at 5°F. High plant density per unit area caused more calyx splitting. Increasing doses of N reduced the number of split calyces while increase in potassium rates enhanced it. Varieties tolerant to calyx splitting are Epson, palmir etc.

Curly tip

This disorder affects the growing tips which curl and become distorted. Tips of the young shoots fail to separate and continuation of growth results in a characteristic curvature. Poor light and other adverse conditions are thought to be the causes of the disorder. Water stress and potassium deficiency are suspected causes for a physiological curly tip and die-back of carnation flowers.

Chrysanthemum

Blindness

It occurs when the night temperature is too low and the days are short at the time when flower buds are forming. A rosetted type of growth is indicative of this difficulty. Center petals that fail to develop can be due to excessive heat; or in dark weather some varieties apparently lack enough food to open the flower. Chlorosis, or yellowing of the upper foliage, is generally associated with over watering, excessive fertilizer in the soil, or insects or diseases attacking the root system. Continued growth of shoots and failure to form flower buds when short days are started the mean night temperature was too low. Sunscald is prevalent on standards in flower in very warm weather. The petals turn brown and dry up.

Gerbera

Bushiness

An abnormality characterized by numerous leaves, short petioles and small laminae, which gives some cultivars of gerbera a bushy appearance known as bushiness. Nodes are not clearly distinguished and no internode elongation is seen.

Stem break

It is common post harvest disorder in cut gerberas. This is mainly caused by water imbalances. It could be ethylene controlled and associated with early senescence associated with water stress.

Yellowing and purple margin

Nitrogen deficiency causes yellowing and early senescence of leaves. Phosphorus deficiency causes pale yellow colour with purple margin. Increase in levels of nitrogen and phosphorus were found to promote development of suckers and improve flowering in gerbera.

Anthurium

Excess light

Leaves appear bleached in the centers and may have brown tips. To control this

problem, shade should be given so as to reduce the light level to 1800-2500 foot-candles.

Gladioli

Fluoride injury

Leaf scorch of gladioli due to the presence of fluorine compounds in the atmosphere which accumulated on the tips of leaves. The injury is associated with heavy application of super phosphate.

Top

12. Postharvest handling practices for cut flowers

Cut flower quality and longevity are influenced by pre and post harvest practices. Nearly 20-40% of the cut flowers produced are lost due to faulty harvesting, post harvest handling, storage, transportation and marketing. These losses can be reduced by careful harvesting, post harvest handling, temperature management, sanitation and judicious use of floral preservatives.

Harvesting

Maturity of the cut flower mainly decides its post harvest life. The flowers must reach certain stage of development before harvesting. Most of the cut flowers are harvested in the early morning or late in the afternoon. Flowers are harvested with sharp knife or secature.

Rose

Harvesting is done at the tight bud stage when the colour is fully developed and the petals have not yet started unfolding.

Gladioli

The spikes are cut in tight bud stage when colour has fully developed in the mature unopened buds leaving 4 leaves on the plant.

Carnation

Standard carnation flowers are harvested when the outer petals unfold nearly perpendicular to the stem. Spray types are harvested when two flowers open and the remaining buds show colour.

Chrysanthemum

Standard flowers are cut soon after the disappearance of green colour in the centre of the flowers and the center petals are fully expanded. Pompons are cut when they are fully developed. Spray types should be cut when the central flower is open and the surrounding flowers are well developed and the varieties which shed pollen badly will have to be cut before they become unsighty. Cutting the stem while the flowers are slightly on the “green” side is preferred because it offers a better quality product for the customer. The stems are harvested by pulling them out and breaking of the root system leaving it behind in the bed/field be ploughed into the soil when bed/field is prepared for next crop.

Orchid

Flowers are harvested when they are fully open as the flowers cut prior to their maturity will wilt before reaching the wholesaler.

Anthurium

Flowers are harvested when the spathe completely unfurls and the spadix is well developed. Harvesting the blooms, when one third of the flowers on the spadix mature, change of colour can be observed that moves from base to tip of spadix. At this stage the flowers are harvested. Harvesting has to be done during cooler parts of the day i.e.) early morning or late evening In general the cut blooms are placed in water held in plastic buckets immediately after cutting from the plant. Delay in keeping in water allows air entry into the stem and causes blockage of the vascular vessels. Cut flowers after harvest should be shifted to pre cooling chambers in refrigerated vehicles having 2-4°C temperature as they deteriorate most rapidly at high temperature. After reaching the cooling chamber, another cut is given above the previous cut in roses, whereas in orchids lower 0.75 cm of the peduncle is cut. In gladioli, 2.5 cm diagonal cut is made to expose maximum capillary tissues for absorbing more water

Pre cooling

Pre cooling removes field heat rapidly from the freshly harvested cut flowers. Precooling lowers respiration rate, water loss and ethylene synthesis. Most of the time, greatest loss occurs due to delay in precooling. Generally two methods of cooling are followed. The first one is room cooling and the other one is forced air-cooling. In room cooling, the flowers are held in buckets which are placed in a cooler. In the forced air cooling system, the flowers packed in perforated boxes are subjected to cool air blasts for a specific period in a closed room to remove field heat. The flowers take 20-30 minutes for cooling in forced cooling depending on the flower type and initial temperature in the box. Proper temperature (1.7°C to 4°C) and relative humidity (90-95%) maintenance are critical to the success of precooling, otherwise the flowers will dessicate.

Postharvest handling practices for important cut flowers

Rose

Roses must be placed in a bucket of water inside the polyhouse immediately after harvesting and transported to cold storage (2-4°C). The length of time depends upon the variety and quality of the roses.The flowers are graded according to the length. It varies from 40-70 cm depending on the variety and packed in 10/12 per bunch

Carnation

After harvest, the flower stems have to be trimmed at the base and should be immediately placed in a bucket of preservative solution of warm and deionized water. A good preservative solution for carnations should be acidic (pH 4.5) with 2-5% sucrose and a biocide not phytotoxic to carnations. After keeping in preservative solution for 2 to 4 hours, flowers should be placed in a refrigerated room at 0-2°C for 12-24 hours. The flowers can be stored for two to four weeks before marketing. For this, the flowers have to be packed in cartons lined with polyethylene film. These cartons should have sufficient vent holes. The full cartons should be pre-cooled with out lid. The plastic is then loosely folded on top of the stems and the lid is closed. These cartons are stored in cool chambers designed to maintained 0°C with good air circulation and a constant relative humidity of 90-95%.

Chrysanthemum

After harvest, the stem have to be cut at equal length (90 cm is the standard), bunched in five putting a rubber band at the base and sliding them into a plastic sleeve and putting the bunches in plastic buckets filled with water. Early morning on the day of shipment (or night before) the bunches can be packed in boxes.

Gerbera

Harvesting is done when outer 2-3 rows of disc florets are perpendicular to the stalk. The heel for the stalk should be cut about 2-3 cm above the base and kept in fresh chlorinated water.

Orchids

Storage

Since most orchid flowers are long-lived on the plants, they should not be harvested until needed. If these are to be cut they should be stored at 5-7°C. At this temperature most orchid flowers can be stored for 10 to 14 days. Plastic film storage is attractive and can be utilized.

Packaging

Packaging is another important aspect in the flower trade. An ideal package should be airtight, water proof, strong enough to withstand handling and small in volume. Many ways are followed to pack orchid flowers. Cymbidium spikes are often packed 100 flowers to a box. Standard florist boxes are used for the packing of Cattleya floors. Hawaiin Dendrobium is packed in 4 dozen sprays per box. Keeping of a wet cotton at the cut end of the flower stem which is wrapped with a polythene wrapper helps to maintain humidity.

Vase- life

Immediately after arrival, the lower 0.75 cm of the peduncle is cut off, and the flower is inserted into a fresh tube of water containing preservative. In case of spray type of orchids, the basal 2.5cm of the stem is cut upon arrival, placed in warm water at 38°C with a preservative and hardened off at 5°C. Foliar application of aluminium chloride at 500ppm, ammonium molybdate at 100 ppm or boric acid at 1000ppm increased the vase-life of Oncidium.. Hydroxyquinoline resulted in additional bloom opening of the flowers and also increased the vase-life.

Anthurium

Flowers can be easily stored at 13°C for 2-3 weeks. The flowers, which are harvested when 3/4th of the length of the spadix colour changes, lasts longer than the other flowers which are harvested either early or late. The average vase life depends upon life of flowers range between 12-24 days depending upon the cultivars. Anthurium is packed in cartons lined with impervious polyethylene sheeting of adequate length and width so that, when packed, the sheet can be folded over to prevent the moisture of the dampened flowers and packing material from dampening the box itself. Newspaper is used to line the carton, and shredded newspaper is used to cushion spathes that are arranged in rows facing opposite directions. Each individual spathe is wrapped and tucked with un-printed newspaper or other white paper. Top |